Precise Hardness Testing for the Toughest Requirements

Rely on our technology for accurate, efficient, and future-ready testing processes.

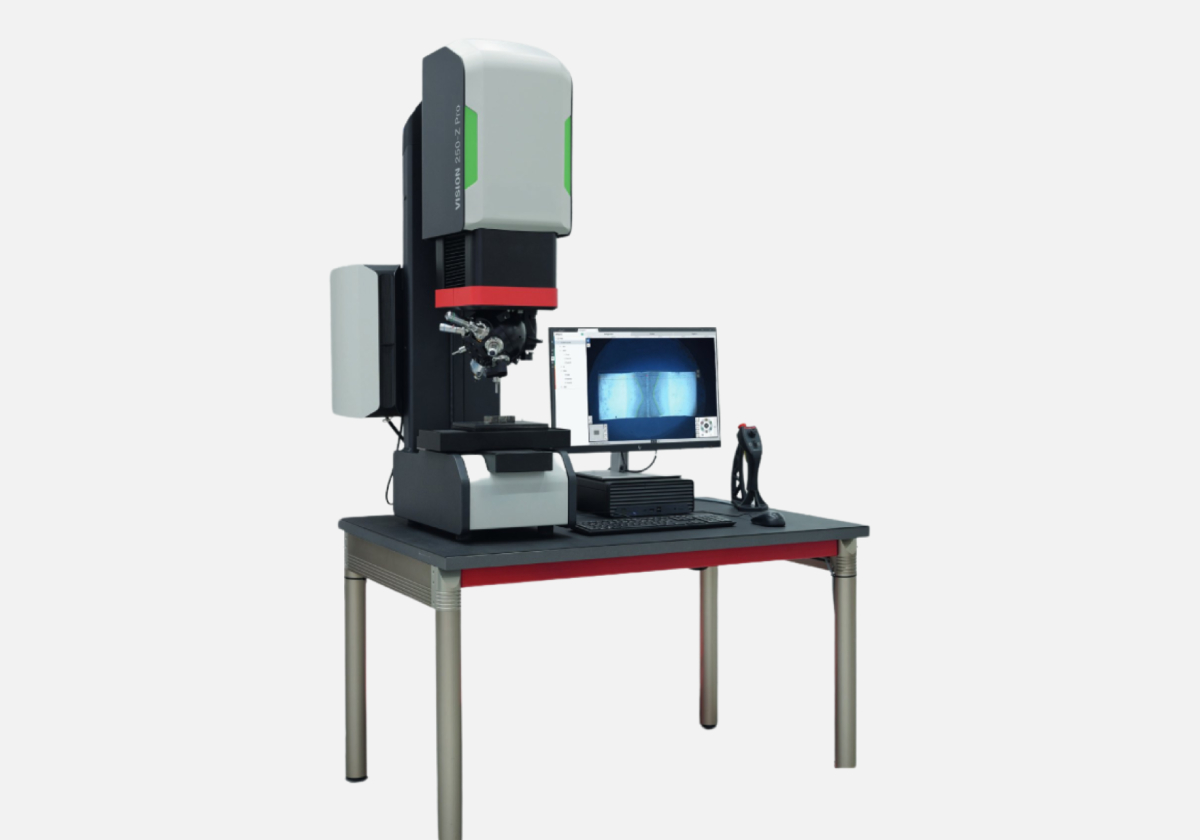

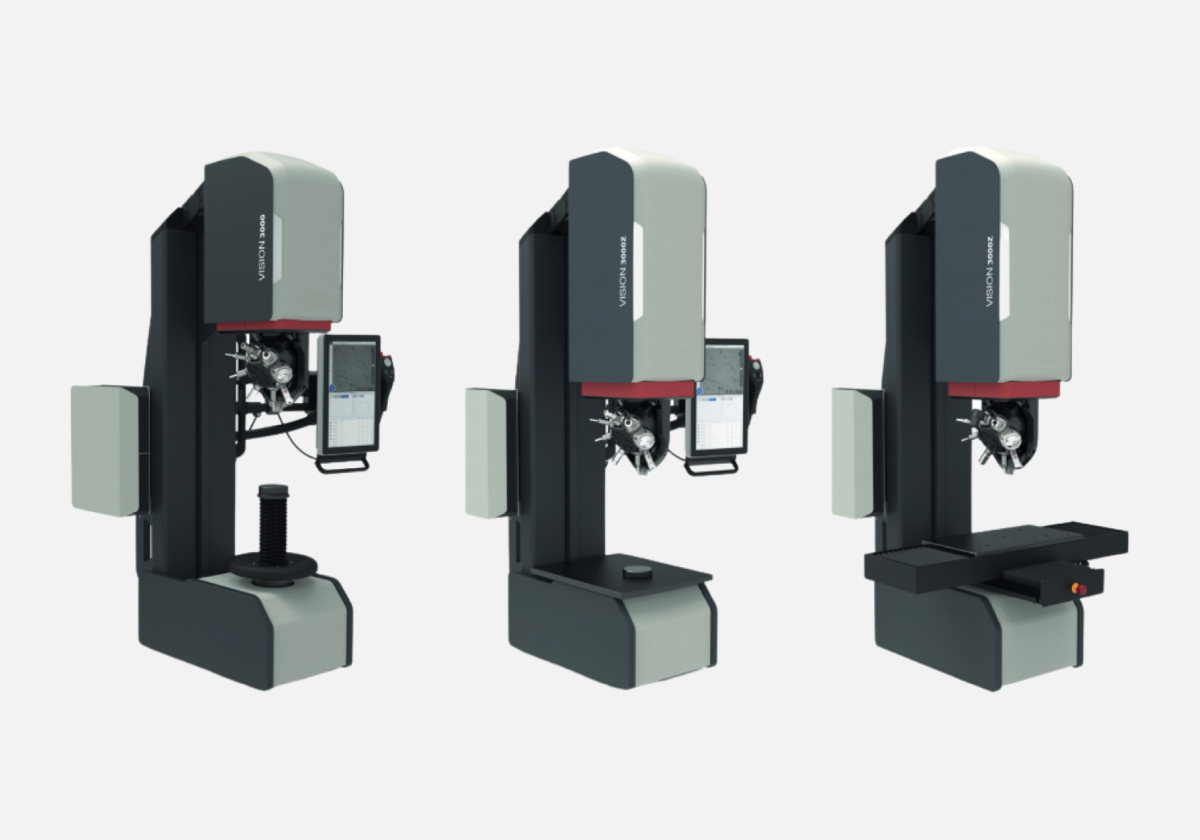

The VisionLine hardness testers deliver precise results for micro and macro hardness tests in industrial and laboratory environments. With a flexible tool changer, intuitive operation and AI-supported evaluation, they are ideal for a wide range of materials and component shapes. Thanks to their robust design and automated functions, they ensure efficiency and reliability, even under demanding testing conditions.

The VisionLine solves a wide variety of testing tasks and delivers efficiency in hardness testing applications. Even in harsh industrial environments, the hardness testing machine operates reliably and complies with the latest applicable standards. Practical templates and comprehensive assistance make hardness testing simple and easy to understand for every user.

Precise hardness values can be determined for different materials and component shapes. Test flat surfaces, tubes, or balls—whether made of steel, copper, aluminum or other metals.

Key benefits and features

- More efficient testing processes and reduced changeover time – thanks to the 8-fold tool changer.

- Patented clamping system: stable fixation and precise results.

- MotionControl: ergonomic operation with various control options.

- Flexibility for changing test requirements with load extension down to 10 gf.

- Easy maintenance and maximum uptime – for uninterrupted productivity.

- ecos™ III – efficient hardness testing software with artificial intelligence.

- Minimisation of operator influence for reliable test results.

- Improved evaluation of hardness indentations – AI Inside.

- Easy administration of user rights – for maximum control and security.

The Right Test Method

Depending on the model, the available load ranges extend from 0.3 kgf to 250 kgf or from 3 kgf to 3000 kgf (optionally from 10 gf).

The universal hardness tester supports various optical and depth difference methods to meet your hardness testing needs. These include standard methods such as Vickers, Brinell, Knoop, and Rockwell. Test results can be converted into various hardness values in compliance with relevant standards.

Advanced Imaging with Maximum Precision

Achieve outstanding precision in your evaluations with our advanced 12-megapixel color camera. Thanks to three zoom levels per lens, you can generate impressively sharp test images directly on your screen. These zoom functions ensure razor-sharp visuals without compromising image quality.

Our versatile lenses cover your entire range of applications, enabling maximum results with minimal effort. Additionally, our user-friendly software ensures fast and accurate hardness value calculations.